Unveiling the Future: Innovations and Insights in Plastic Materials

In today's rapidly evolving world, plastic materials play a crucial role in countless industries and everyday life. From packaging solutions to automotive components, the versatility and durability of plastics have made them indispensable. However, as we become increasingly aware of environmental concerns, innovation in plastic materials is taking center stage. This article will explore the groundbreaking developments in plastic technology, emphasizing sustainable practices and novel applications that pave the way for a greener future.

As we delve into this exciting realm, it is essential to recognize how innovations in plastic materials are not only enhancing performance but also addressing pressing global challenges. Researchers and manufacturers are pushing the boundaries to create materials that are not only functional but also environmentally friendly. Join us as we unveil the latest insights, trends, and innovations that are transforming the landscape of plastic materials and shaping their role in our society for years to come.

Advancements in Plastic Technology

The field of plastic technology is rapidly evolving, driven by the demands for sustainability and performance. Recent innovations have led to the development of biodegradable plastics that serve as alternatives to traditional petroleum-based materials. These new formulations break down more easily in the environment, reducing plastic waste and its harmful impact. Companies are investing in research to enhance the properties of biodegradable plastics, making them more durable and versatile for various applications.

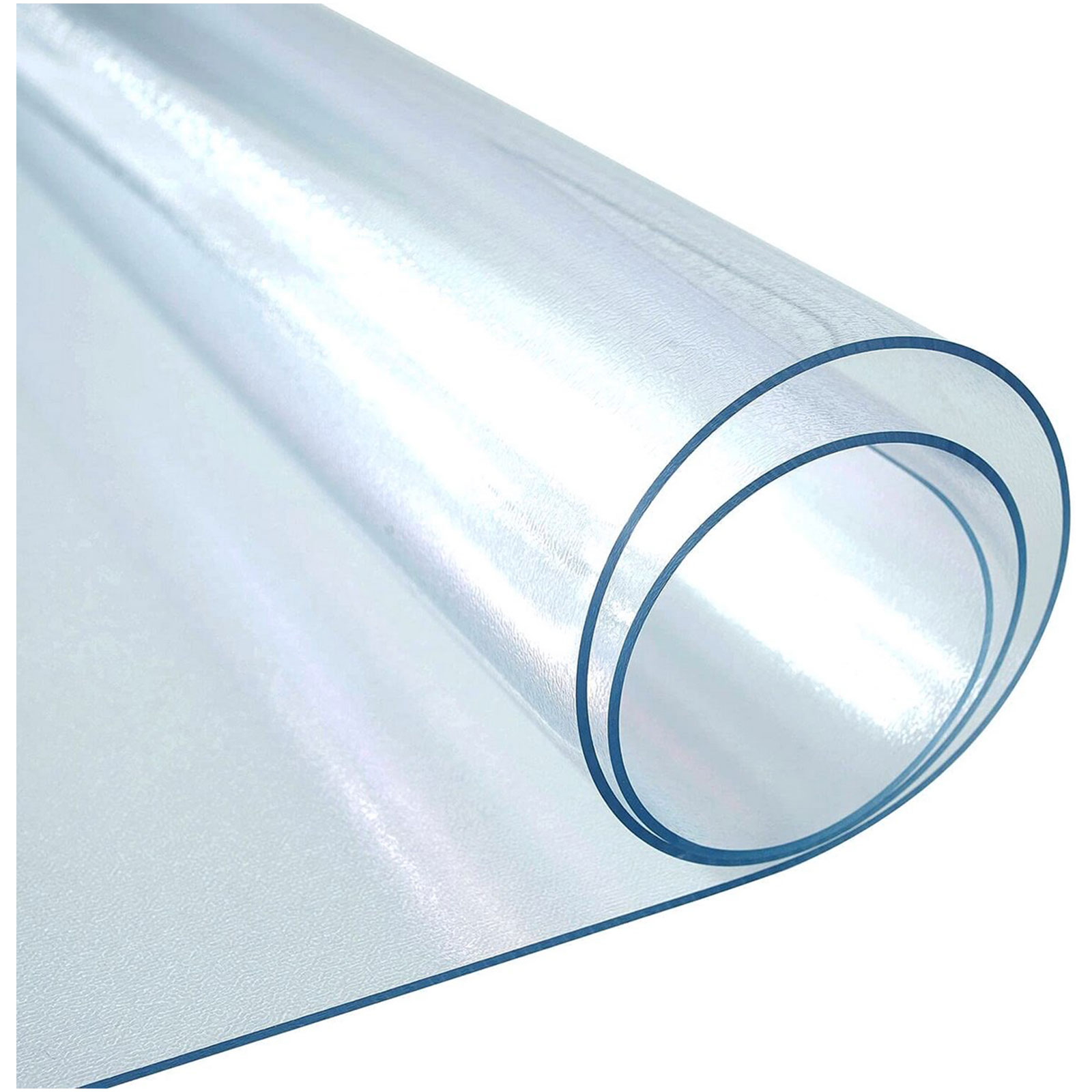

Another significant advancement is the introduction of high-performance plastics that can withstand extreme conditions. plaque plexiglas sur mesure These materials are engineered for applications in aerospace, automotive, and electronics, where traditional plastics may fail. Innovations such as thermoplastics and thermosetting plastics are being designed to resist high temperatures and chemical exposure, enabling their use in sophisticated technologies. This growth in high-performance plastics is crucial for meeting the escalating demands of modern manufacturing.

Furthermore, the integration of smart technology into plastic materials is transforming their functionality. Smart plastics embedded with sensors can monitor conditions such as temperature, pressure, or stress, providing real-time data for applications ranging from healthcare devices to smart packaging. This capability not only enhances the usability of plastic materials but also supports the development of innovative solutions that improve efficiency and safety across various industries. As these advancements continue, they promise to redefine how plastic materials are produced and used in our daily lives.

Sustainability in Plastic Production

The production of plastic materials has long been associated with environmental concerns, primarily due to the reliance on fossil fuels and the generation of waste. However, recent advancements are paving the way for more sustainable practices. Manufacturers are increasingly turning to bio-based plastics made from renewable resources such as corn starch or sugarcane. These alternatives not only reduce dependence on petroleum but also have the potential to lower greenhouse gas emissions during production.

In addition to utilizing renewable resources, the industry is making strides in recycling technologies. Innovations in chemical recycling allow for a wider range of plastics to be processed and reintroduced into the production cycle. This not only helps divert plastic waste from landfills but also minimizes the need for virgin materials. Integrated recycling methods are becoming essential in achieving a circular economy, where plastic materials can be continuously reused and reduced in overall consumption.

Furthermore, the concept of eco-design is gaining traction among plastic manufacturers. By considering the entire lifecycle of plastic products from conception to disposal, companies can create materials that are not only functional and durable but also environmentally friendly. This includes designing for easier recyclability and reducing the toxicity of additives used in plastic. By prioritizing sustainability in plastic production, the industry is moving towards a future where plastic materials can be part of a balanced ecosystem, benefiting both society and the environment.

Future Applications of Plastic Materials

The future of plastic materials promises exciting innovations that could reshape numerous industries. One of the key areas is sustainable packaging. With the increasing demand for eco-friendly solutions, advancements in biodegradable and compostable plastics are gaining traction. Companies are exploring new formulations that not only reduce environmental impact but also maintain product integrity and shelf life. These innovations are poised to lessen reliance on traditional plastics, aligning with global sustainability goals.

Another promising application of plastic materials lies in the medical field. As technology evolves, so do the capabilities of plastics in producing safer and more effective medical devices. Innovations in biocompatible plastics are making procedures more efficient, facilitating the development of implants and prosthetics tailored to individual patient needs. Moreover, 3D printing of medical appliances using specialized plastics offers rapid prototyping, enabling customized solutions that were previously unattainable.

Additionally, the automotive and aerospace sectors are investing heavily in lightweight plastic materials to improve fuel efficiency and reduce emissions. Ongoing research into advanced polymers promises to yield stronger and more durable components that can withstand harsh environments while minimizing weight. This shift towards incorporating high-performance plastics in vehicle production is expected to enhance overall efficiency and performance, marking a significant step towards greener transportation solutions.